SL800 — Ultrasonic Set Quick and economic detection of compressed air leaks

Términos y condiciones

Garantía de devolución de 30 días

Envío: 2-3 días laborales

ULTRASOUND MEASURING INSTRUMENT SL800

Quick and economic detection of compressed air leaks

Quick and economic detection of compressed air leaks

With this professional ultrasonic detector set you can locate leakages in compressed air supply networks, plant systems and at concealed pipelines quickly and inexpensively without contact even from a distance of several metres.

In case of leaking gas even a tiny point of leakage in the compressed air line is sufficient and leads to increased friction, generating a sound inaudible for humans in the ultrasonic frequency range.

Wear abrasion at movable machine parts becomes noticeable in the same way.

These sound vibrations caused by flow friction are received by the probe of the SL800R and transformed into audible sound by way of high-performance transducer technology, which can then be played over soundproof headphones and additionally displayed as an indicator value via a 10-piece LED bar graph.

The combined visual and audible detection with adjustable headphone volume permits focused working even in poor lighting conditions and noisy surroundings.

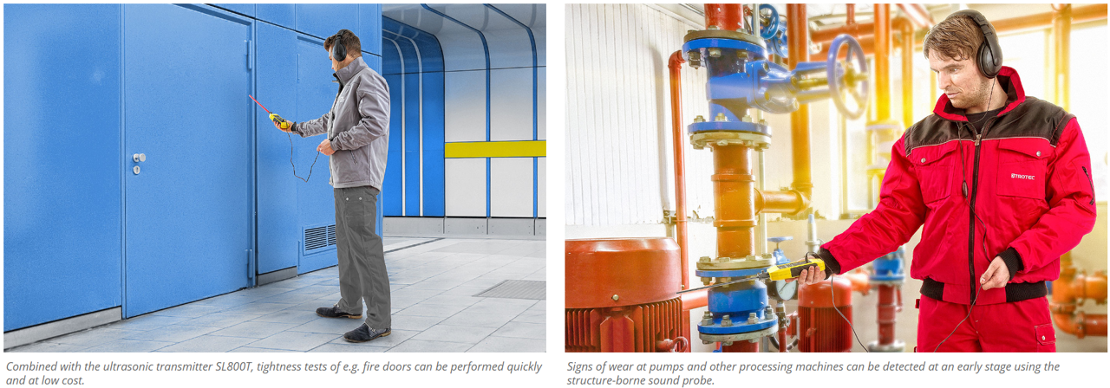

To test the tightness of pressureless systems such as tanks, containers, or climatic chambers and ventilation systems, this system can be subjected to ultrasound using the SL800T transmitter, which is also included in the set.

In case of leaking gas even a tiny point of leakage in the compressed air line is sufficient and leads to increased friction, generating a sound inaudible for humans in the ultrasonic frequency range.

Wear abrasion at movable machine parts becomes noticeable in the same way.

These sound vibrations caused by flow friction are received by the probe of the SL800R and transformed into audible sound by way of high-performance transducer technology, which can then be played over soundproof headphones and additionally displayed as an indicator value via a 10-piece LED bar graph.

The combined visual and audible detection with adjustable headphone volume permits focused working even in poor lighting conditions and noisy surroundings.

To test the tightness of pressureless systems such as tanks, containers, or climatic chambers and ventilation systems, this system can be subjected to ultrasound using the SL800T transmitter, which is also included in the set.

This ultrasound measuring instrument is supplied as a complete set with exchangeable probes and an ultrasonic transmitter:

Included in this set are the ultrasonic detector SL800R and the ultrasonic transmitter SL800T – both delivered ready for use incl. batteries – an airborne and structure-borne sound probe each for the SL800R and soundproof headphones with volume control – all fitting into the carry case.

Included in this set are the ultrasonic detector SL800R and the ultrasonic transmitter SL800T – both delivered ready for use incl. batteries – an airborne and structure-borne sound probe each for the SL800R and soundproof headphones with volume control – all fitting into the carry case.

This variety of potential applications is made possible by ultrasonic detection using the SL800 set:

Una vez que el usuario haya visto al menos un producto se mostrará este snippet.